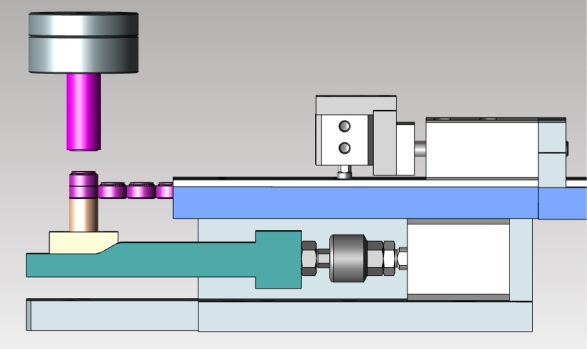

Research and development

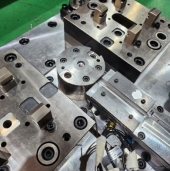

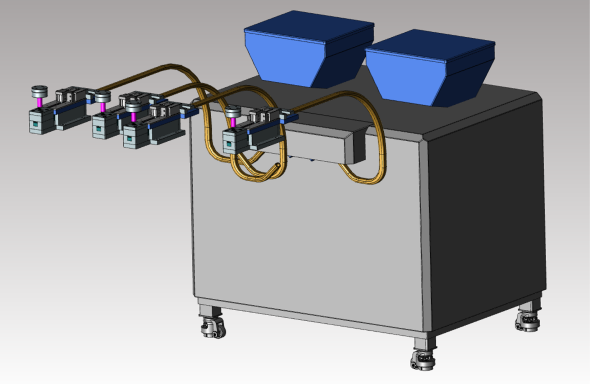

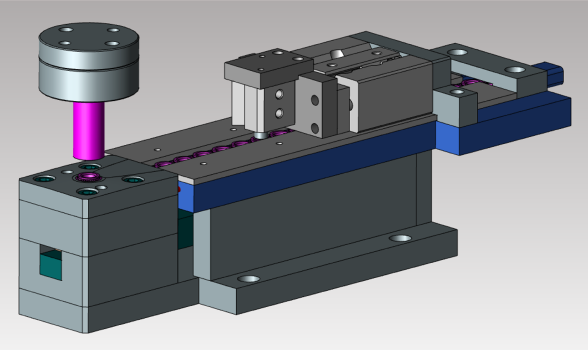

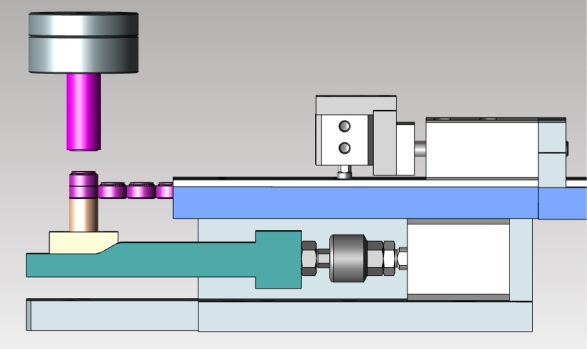

Hanyeong Hitech has developed innovative technology and

Leading the future of the mold industry through customer-centered services.

Hanyeong Hitech has developed innovative technology and

Leading the future of the mold industry through customer-centered services.

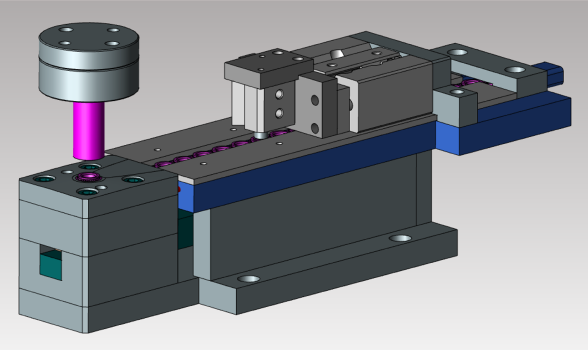

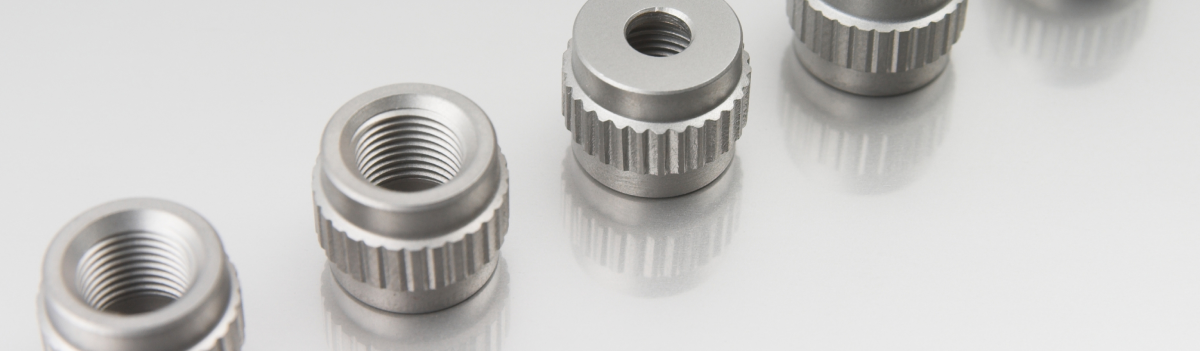

| Screw Thread Specification |

Pitch | Material | D (MAX) |

B ±0.2 |

H ±0.1 |

h (MAX) |

counterpart | |||

| C-Steel | Stainless Steel |

Minimum Plate Thickness |

Minimum Plate Thickness |

Mounting Hole Position※1 (Min) |

||||||

| M2 | 0.40 | TC-M2-0 | TCS-M2-0 | 4.22 | 6.3 | 1.5 | 0.76 | 0.8 | 4.25 | 4.8 |

| TC-M2-1 | TCS-M2-1 | 0.97 | 1.0 | |||||||

| TC-M2-2 | TCS-M2-2 | 1.37 | 1.4 | |||||||

| M2.5 | 0.45 | TC-M2.5-0 | TCS-M2.5-0 | 4.22 | 6.3 | 1.5 | 0.76 | 0.8 | 4.25 | 4.8 |

| TC-M2.5-1 | TCS-M2.5-1 | 0.97 | 1.0 | |||||||

| TC-M2.5-2 | TCS-M2.5-2 | 1.37 | 1.4 | |||||||

| M3 | 0.50 | TC-M3-0 | TCS-M3-0 | 4.22 | 6.3 | 1.5 | 0.76 | 0.8 | 4.25 | 4.8 |

| TC-M3-1 | TCS-M3-1 | 0.97 | 1.0 | |||||||

| TC-M3-2 | TCS-M3-2 | 1.37 | 1.4 | |||||||

| M3.5 | 0.60 | TC-M3.5-0 | TCS-M3.5-0 | 4.73 | 7.1 | 1.5 | 0.76 | 0.8 | 4.75 | 5.8 |

| TC-M3.5-1 | TCS-M3.5-1 | 0.97 | 1.0 | |||||||

| TC-M3.5-2 | TCS-M3.5-2 | 1.37 | 1.4 | |||||||

| M4 | 0.70 | TC-M4-0 | TCS-M4-0 | 5.38 | 7.9 | 2.0 | 0.76 | 0.8 | 5.40 | 6.9 |

| TC-M4-1 | TCS-M4-1 | 0.97 | 1.0 | |||||||

| TC-M4-2 | TCS-M4-2 | 1.37 | 1.4 | |||||||

| M5 | 0.80 | TC-M5-0 | TCS-M5-0 | 6.38 | 8.7 | 2.0 | 0.76 | 0.8 | 6.40 | 7.1 |

| TC-M5-1 | TCS-M5-1 | 0.97 | 1.0 | |||||||

| TC-M5-2 | TCS-M5-2 | 1.37 | 1.4 | |||||||

| M6 | 1.00 | TC-M6-1 | TCS-M6-1 | 8.72 | 11.05 | 4.1 | 0.76 | 0.8 | 8.75 | 8.8 |

| TC-M6-2 | TCS-M6-2 | 0.97 | 1.0 | |||||||

| TC-M6-3 | TCS-M6-3 | 2.21 | 1.4 | |||||||

| M8 | 1.25 | TC-M8-2 | TCS-M8-2 | 10.44 | 12.65 | 5.5 | 1.37 | 1.4 | 10.50 | 9.7 |

| TC-M8-3 | TCS-M8-3 | 2.21 | 2.3 | |||||||

| M10 | 1.50 | TC-M10-3 | TCS-M10-3 | 12.65 | 15.00 | 7.0 | 1.95 | 2.0 | 12.70 | 11.6 |

| M12 | 1.75 | TC-M12-3 | TCS-M12-3 | 14.65 | 17.00 | 8.0 | 1.95 | 2.0 | 14.70 | 13.5 |

| TC-M12-4 | TCS-M12-4 | 20.00 | 2.8 | 3.0 | 14.70 | |||||